Introduction to Materials Processing (MS 502)

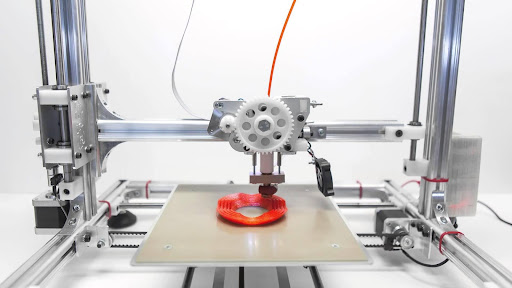

This course contains two major part of Materials Science. The selection of materials based on their properties and the processing of the materials. Understanding the properties of different materials, such as metals, ceramics, polymers, and composites, is fundamental. In this course students will learn how material properties influence selection for specific applications. In Materials Processing Techniques Casting, Forming, Joining, Machining, Powder Metallurgy, Additive Manufacturing processes will be explained. Another processing is Heat Treatment in which Annealing, Quenching, and Tempering will be discussed. There are various Surface Treatments like Coatings, Surface Modification along with various Quality Control and Testing like Non-Destructive Testing (NDT), Mechanical Testing etc.

Advanced Materials Characterization Techniques (MS 503)

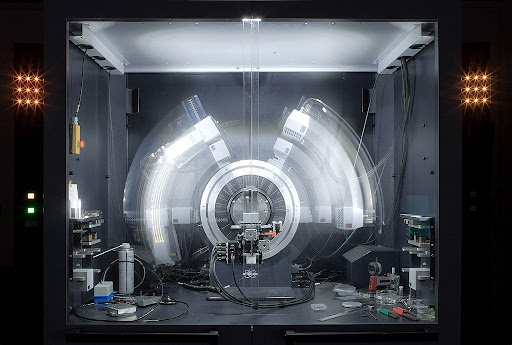

Several characterization and their analysis should be done before applying any material in practical use. This is the integral part of the materials designing and Engineering. In this course Microscopy experiments like Scanning Electron Microscopy (SEM), Transmission Electron Microscopy (TEM), Lamella preparation for TEM using various advanced techniques like FIB, X-ray Diffraction (XRD), Spectroscopy Techniques like X-ray Photoelectron Spectroscopy (XPS), Raman Spectroscopy, Infrared Spectroscopy (IR), Nuclear Magnetic Resonance (NMR), Thermal Analysis Techniques like Differential Scanning Calorimetry (DSC), Thermogravimetric Analysis (TGA), Mechanical testing like Nano Indentation and the techniques to analysis the data using different software will be covered.

Surface Engineering (MS 509)

Surface engineering is a multidisciplinary field of materials science and engineering that focuses on modifying the properties and performance of a material's surface while maintaining the bulk properties. The goal of surface engineering is to improve the surface properties of materials to meet specific functional requirements, such as increased wear resistance, improved corrosion resistance, enhanced tribological properties, better adhesion, or reduced friction. It plays a crucial role in various industries, including automotive, aerospace, electronics, and manufacturing. Surface Modification Techniques (like Coatings, Surface Hardening, Heat Treatment, Surface Alloying, Surface Cleaning and Pre-treatment), Thin Film Deposition, Plasma and Ion Beam Techniques, Laser Surface Modification are the key aspects of this course. Surface engineering is a dynamic field that continues to evolve with advancements in materials and technologies. It plays a vital role in extending the service life and enhancing the performance of a wide range of products and components across various industries.

Structural and Functional Properties of Materials (MS 504)

This course provides students with an understanding of the relationships between the structure, properties, and functions of various materials. An overview of this course is Introduction to Materials Science and Engineering, Atomic and Molecular Structure, Microstructure, Mechanical Properties, Thermal Properties, Electrical and Magnetic Properties, Optical Properties, Chemical Properties, Phase Diagrams, Material Classes, Materials Processing, Structure-Property Relationships, Functional Materials, Applications, Materials Testing and Characterization, Materials Selection and Design, Environmental and Sustainability Considerations, Case Studies and Projects. The course on structural and functional properties of materials provides a foundation for understanding the behaviour of materials in different applications. This course is essential for students in materials science and engineering as well as for professionals working in industries where materials play a critical role.

Composite Science and Technology (MS 510)

This course focuses on the study of composite materials, which are materials made by combining two or more distinct materials with different properties to achieve enhanced performance characteristics. Composite materials are widely used in various industries, including aerospace, automotive, construction, and sports equipment. This course contains Introduction to Composites, Composite Materials Classification, Reinforcement Materials, Matrix Materials, Composite Fabrication Techniques, Mechanical Properties of Composites, Thermal Properties of Composites, Electrical and Thermal Conductivity, Failure Analysis and Fracture Mechanics, Environmental Durability, Design and Optimization of Composites, Applications of Composite Materials, Quality Control and Testing, Composite Failure Analysis, Sustainability and Recycling, Research and Development in Composites. This course equips students with the knowledge and skills required to work with composite materials, from designing composite structures to understanding their mechanical and thermal behaviour. It is essential for students pursuing careers in materials science, aerospace engineering, automotive engineering, and other fields where composites play a crucial role.

Advanced Building Materials (MS 515)

These courses is designed to provide students with a deeper understanding of materials science and their practical applications in the construction industry. The concepts that might be covered in such a course are Material Properties and Selection, Nanotechnology in Construction, Sustainable Building Materials, High-Performance Concrete, Advanced Steel and Metal Alloys, Smart Materials, Energy-Efficient Insulation and Coatings, Composite Materials, Biomimetic Materials, Testing and Evaluation, Case Studies, Regulations and Standards, Cost-Benefit Analysis, Sustainability and Environmental Impact, Future Trends. These are some of the core topics you can expect to encounter in an "Advanced Building Materials" course. Keep in mind that the specific curriculum may vary depending on the institution and the level of the course (undergraduate or graduate). Such courses aim to equip students with the knowledge and skills needed to stay at the forefront of construction technology and sustainable building practices.

Alloy Development and Heat Treatment (MS 512)

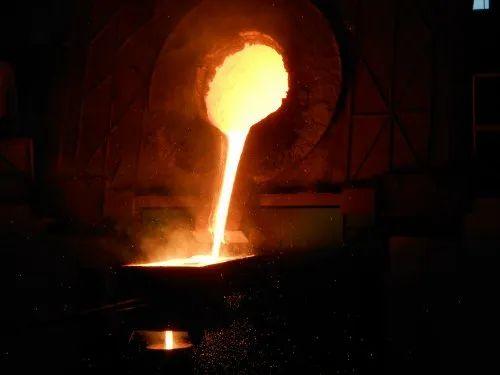

This course explores the design, development, and processing of alloys, as well as the various heat treatment techniques used to modify the properties of alloys for specific applications. The key topics and concepts that are covered in such this course Introduction to Alloys, Alloy Composition and Phases, Alloy Design and Selection, Alloy Processing, Heat Treatment Fundamentals, Annealing, Quenching and Tempering, Precipitation Hardening, Surface Treatments, Welding and Heat-Affected Zone, Failure Analysis, Quality Control and Testing, Advanced Alloys and Applications, Environmental and Sustainability Considerations, Future Trends, Throughout the course, students may engage in laboratory work and experiments to gain hands-on experience with alloy synthesis, heat treatment processes, and material characterization techniques. Additionally, case studies and industry guest lectures may be incorporated to provide real-world context for the course material. Overall, the course aims to equip students with a deep understanding of alloys and heat treatment techniques, preparing them for careers in materials science, metallurgy, and related fields.

Metallurgical Thermodynamics and Kinetics (MM 205)

Metallurgical thermodynamics and kinetics are fundamental concepts in the field of metallurgy and materials science. They play a crucial role in understanding the behaviour of metals and alloys, as well as in the design and optimization of processes used in metallurgical industries. Metallurgical thermodynamics deals with the study of the energy changes and equilibrium conditions in metallurgical processes. Key concepts and principles include: Gibbs Free Energy (G), Enthalpy (H), Entropy (S), Phase Diagrams, Reaction Equilibrium. Where is Metallurgical kinetics focuses on the rates at which processes occur in metallurgical systems. Key concepts and principles include Reaction Rate, Activation Energy, Diffusion, Nucleation and Growth, Heat Treatment, The combination of thermodynamics and kinetics allows metallurgists and materials scientists to predict and control the behaviour of materials under various processing conditions. It is instrumental in optimizing processes for producing alloys with desired properties, improving the performance of materials, and ensuring the reliability of structural components in industries such as aerospace, automotive, and construction.

Phase Transformation and Diffusion (MM 204)

Phase transformations involve the changes in the microstructure and phase composition of materials as a function of temperature, pressure, and composition. Key aspects typically covered in this course Phase Diagrams, Solidification, Solid-State Phase Transformations, Heat Treatment. Diffusion is the process of atomic